| Payment Type: | L/C,T/T,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 20 Days |

Basic Info

Certification: CE, ISO

Dryer Type: Roller Veneer Dryer

Veneer Thickness: 0.5-5mm

Working Width: 3m

Additional Info

Packaging: Export packing

Productivity: 15-100cbm per day

Brand: SHINE

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 10 set per month

Certificate: ISO;CE

HS Code: 8419320000

Port: Qingdao

Product Description

The main components of Shine maple veneer drying machine are as follows: 1. Drying system : the veneer dryer adopts the most scientific drying principle , and the hot air in the hot air stove is injected directly into the upper and lower bellows of the machine by centrifugal blower. The hot air blows to the upper and lower sides of the running veneer through the nozzles of the upper and lower bellows, so that the veneer is heated evenly and thus plays the role of drying 2.Control system: Adopt endless gearbox to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect. 3.Transmission system : the veneer is fed into the machine through the feed inlet vertically, and the chain drives the upper and lower rows of rollers, running relatively. The veneer moves forward by the self-weight pressure of the upper roll, and during the veneer passes through the two rollers and the upper and lower air nozzles, it achieves the effect of drying and ironing. So the veneer dried by this machine is flat, smooth and without marks. 4. Heating system: Steam heating, heat conduction oil heating, hot stove type heating,waste wood or other biomass materials. Users can choose one.

1. The veneer after drying by Shine veneer dryer is smooth and the moisture content is uniform, and the high temperature drum has direct contact with the wet veneer for heat transfer, and the heat efficiency is high, the heat loss is small, and the heat loss is reduced. the selling price for veneer dried by roller veneer dryer is higher than natural drying.

2.The roller veneer drying machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect .

3.Shine core veneer dryer or face veneer dryer covers a small area, less ancillary equipment, convenient for transportation, quick installation, and can be put into use quickly and conveniently.

4.Standardized production models, can make different sections or decks according to different capacity requirements, which can meet different customers' requirements.

5.Each section with heat exchanger, which can make full use of the heat and achieve the best drying effect.

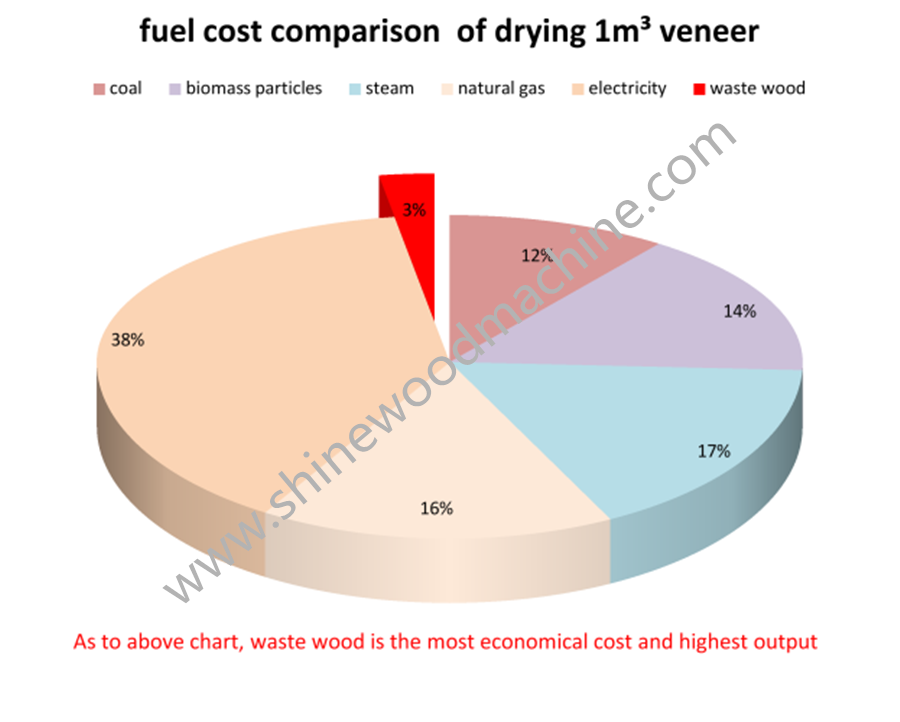

6. The fuel source can be the waste wood after peeling or the tree bark ,which can reduce the fuel cost greatly for the user.

Parameter

Model

DHS20M

DHS24M

DHS28M

DHS32M

DHS36M

DHS40M

Work

width(m)

3

3

3

3

3

3

Deck

2

2

2

2

2

2

Veneer thickness(mm)

0.5-5

0.5-5

0.5-5

0.5-5

0.5-5

0.5-5

Heating

area (m)

16

20

24

28

32

36

Cooling

area (m)

4

4

4

4

4

4

Initial

water content(%)

50-80

50-80

50-80

50-80

50-80

50-80

Finished

water content(%)

10

10

10

10

10

10

Drying

capacity (m³/h)

0.8-1.1

1.1-1.4

1.5-1.8

1.8-2.2

2-2.5

2.4-2.7

Heat

exhaustion(10000

kcal)

28-38.5

38.5-49

52.5-63

63-77

70-87.5

84-94.5

Total

power (kw) about

66

77

88

114

117

121

Overall

size LxWxH(m)

25*4.5

29*4.5

33*4.5

37*4.5

41*4.5

45*4.5

Shandong Shine Machinery Co.,Ltd is a large-scale enterprise specializing in R&D and production of veneer rotary cutting and veneer dryer equipment under the Shandong Wanda Heavy Industry Co., Ltd. Since its inception, the company has been adhering to the vision of [making first-class corporate contributions, building first-rate enterprise talent, creating first-class corporate brand",implementing modern enterprise management system, using new sales concepts and service systems, and investing 20 million yuan in scientific research each year. It also combine industrial universities to study high-end technology, so that Shine's veneer dryer products are always at the forefront of the industry's technology.

The company is located at the intersection of National Road 105 and National Road 308. It has 10 standardized workshops, covers an area of 70000 square meter, and has a building area of 12,000 square meters. It has 150 sets of various equipments and has complete machining, heat treatment, punching, welding, and assembly, painting these six production lines.The advanced equipment, exquisite craftsmanship, and advanced research and development make the [Shine" veneer dryer products have many advantages such as reasonable design, reliable performance, high quality, low energy consumption, easy operation, and high output. Products are sold to various provinces and cities in the country, and exported to Russia, South Africa, Southeast Asia and many other countries and regions.

The company's veneer dryer line and veneer peeling line have won the unanimous praise of our customers with high precision and high cost performance. With perseverance in the spirit of struggle and work attitude of excellence.Shine Intelligent will leave a solid footprint in the process of China's industrial modernization and the development of urban development.

To provide value-added services and solution to customers is the purpose of Shine Machinery. Integrity casts brand and brand leads the market. With our efforts and the trust of our customers, we and our customers will be more successful.

© 2019 CHINA WAY. All Rights Reserved. Shandong Shine Machinery Co.,Ltd, Inc. All rights reserved. site map. sitemap.html