| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 10 Days |

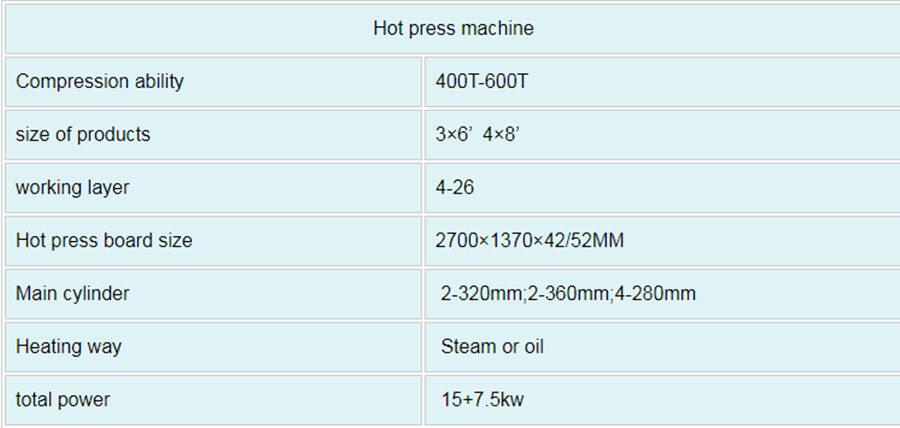

Basic Info

Work Forms: Hydraulic Pressure

Processing Technics: Hot Press

Structure: Box Type

Pressing Shape: Flat Press

Platen Surface Pressure: High Pressure

Pressing Layer: Multi Layer

Work Mode: Continuous

Controlling Mode: CNC

Automatic Grade: Automatic

Certification: CE, ISO

Additional Info

Packaging: Export packing

Productivity: 400-600T

Brand: SHINE

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 100 set per month

Certificate: CE ; ISO

HS Code: 8465960000

Port: Qingdao

Product Description

Plywood hot press machines is fit for the furniture factory or panel secondary processing plant, which can make lamination for furniture panel,building partition, wooden door or laminate all kinds of decorative material on man-made board. Hot press plywood laminating machine also can be used for drying or leveling veneer.Plywood hot press machines is mainly used in woodworking field . It is one of the important machines for plywood production line .sometimes it can be used as veneer dryer instead of core veneer dryer machine.

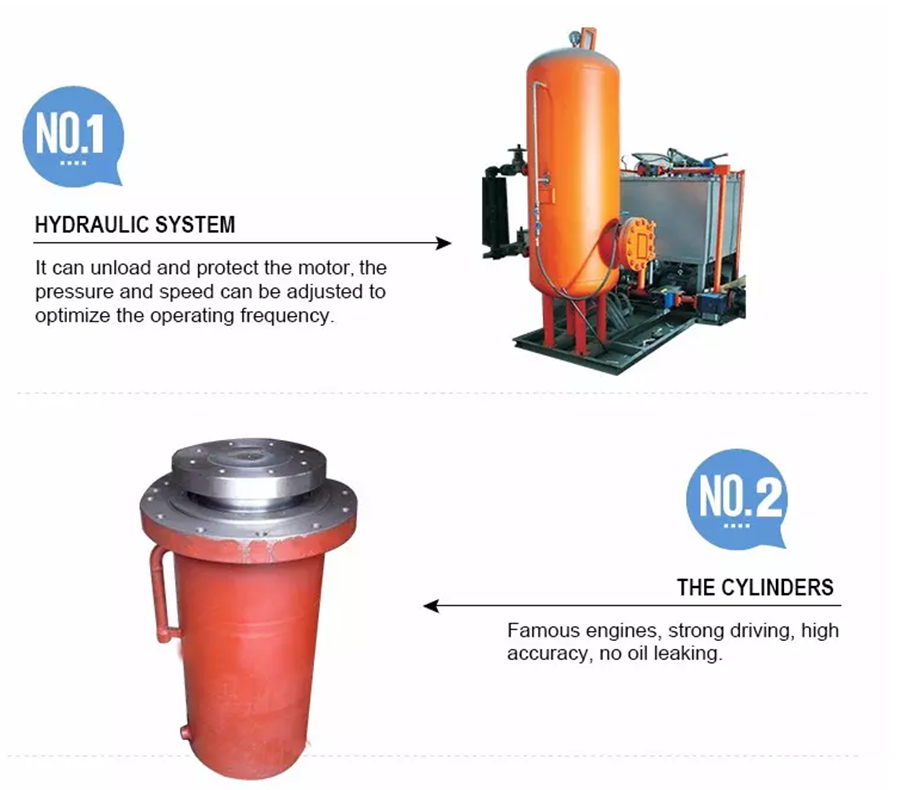

1. PLC programmable control system so that it smooth,rapid closure,stable and effective

2.Cylinder:It is worked through excellent CNC precision machine tool.

3.It can lift the hot platen,close the separation,add the pressure,keep the pressure,keep time, descend the hot platen and so on.

4.As to the oil heater,it is adjustable,safe, uniform temperature,energy saving and so on.

5.It uses high quality oil envelop so as to avoid of oil leaking.

6.Heating system:It can be heated by steam boiler,oil heater or electric oil heater.

The machine can make plywood,particle board,chip board, fibreboard,decorative sheet,etc.

© 2019 CHINA WAY. All Rights Reserved. Shandong Shine Machinery Co.,Ltd, Inc. All rights reserved. site map. sitemap.html